Site & User Requirements

Public Safety

Electrocution can occur from unauthorised access or by a cable fault that causes the pit structure to lid to become live.

To prevent lids and covers from becoming live, metal components within the enclosure should be kept away from electrical cables. Typical industry pits contain locking bars which intrude into the space of the enclosure.

ACO recommends either barless locking lid systems (PowerLok®) or the use of access covers. ACO also offers a range of non metallic lids for light duty applications and traafficable steel lids which may be coated with a non conductive anti-slip coating. Contact ACO for details.

For the protection of pedestrians, ACO recommends the top surface of all lids and covers to provide at least the same slip resistance as the adjacent pavement or meet the requirements of AS/NZS 4586 and HB 197 for a minimum slip classification of R10 for external services. ACO's recessed access covers will accommodate the designer's choice of pavement topping.

Worker Safety

For maintenance operations, some basic precautions should be exercised.

Field maintenance crews trained to service communication pits should not perform any work on pits suspected of containing unprotected electrical cables, terminations or joints (whether sealed or not). Only specialist authorised electrical should carry out work on electrical pits.

A cable enclosure must provide reasonable protection against damage from environmental and other external influences. Typically this includes exposure to weather (UV and water), flora, fauna, galvanic action and the accumulation of dust.

Excessive ingress of any, or a combination of the above factors, may make cable enclosures hazardous as well as causing damage to their contents.

The degree of protection provided by a lid or access cover against the ingress of water or foreign objects, (needles, fingers, etc.) is expressed as an IP (International Protection) rating, in accordance with AS/NZS 60529. AS/NZS 2053.1 applies this to all conduits and fittings and AS/ACIF S008 applies this specifically to communications enclosures.

Field maintenance crews should always check for the presence of hidden hazards such as dangerous gases, reptiles, insects or sharp objects.

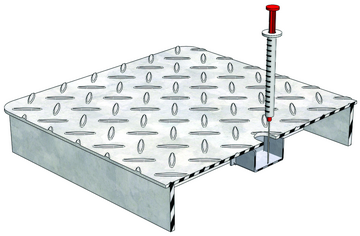

In certain areas of high drug use, hypodermic needles can be disposed of by pushing the needle through the lifting keyhole of the cover into the pit below. If this is a concern, ACO recommends an access cover. Alternatively, ACO's steel lids are fitted with syringe guards and plugs are available for all non-locking lids. Additionally, PowerLok® lids are designed with concealed keyholes. All of ACO's lids and covers meet up to IP4X, AS/NZS 60529, if keyhole plugs are used. Contact ACO for specific IP ratings and definitions for each lid/cover.

The National Code of Practice for Manual Handling recommends a maximum unassisted lifting weight of 55kg. However, it highlights that as weight increases from 16kg to 55kg, safety of individuals doing the lifting is compromised.

ACO's steel lids do not exceed a lifting weight of 25kg, meeting the requirements of regulatory authorities for steel lids. ACO also offers a range of lid lifters and a NATA certified pit lifter to facilitate installation and maintenance. Product lifting weights are also specified on product parts lists.

Water

AS/NZS 3000 requires enclosures that are exposed to weather, provide protection by 'adequate means'. Contractors can improve the protection of cables against ingress of moisture and termite attack. HB 29 provides details with respect to communication cables.

Entry holes for conduits should be capable of being sealed to prevent siltation. cable jointing pits should contain connectors that are suitably selected, enclosed, positioned and supported to prevent ingress of dust or moisture.

Cable enclosures are not designed to be waterproof. A reasonable degree of weather resistance can be achieved by sealing edges of covers and lifting holes each time the cover is removed for servicing. ACO, however recommends Rhinocast® access covers are used to meet the gas and water tightness requirements of AS/NZS 3996. For further information on ensuring weather resistance of enclosures, contact ACO.

Pit drainage is recommended particularly for pits positioned at sag points.

It is extremely hazardous to reach into a pit to handle cables if it is filled with water, particularly if the enclosure houses electrical cables and joints. It should be noted that pits with superior electrical insulation properties such as plastic and polymer concrete can hold water which may be live despite the surrounding earth/pavement appearing inert and safe. HB 29 recommends the use of non conductive snags to lift communications cables and connectors out of the water if drainage of the pit is not practical.